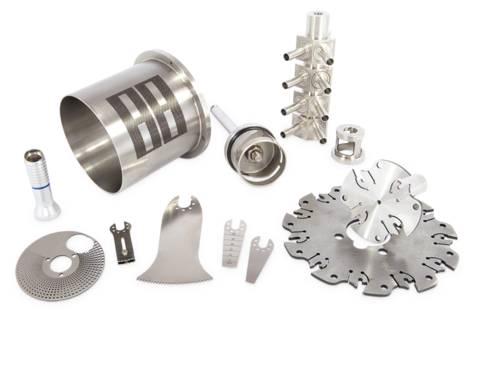

PRECISION WELDING

THE PERFECT TECHNOLOGY FOR PRECISE, DELICATE AND ATTRACTIVE BONDS

Precision welding is mainly used for metals. The focal point of the laser beam melts the metals in just a few milliseconds. Since this is a so-called fusion-welding process, there is usually no need for additional materials. Spot welding as well as seam welding are distinguished by particularly strong and dense bonds with materials that stay free of cracks.

This method also ensures that the welds have no distortions or pores, since the laser beam transmits a precisely measured amount of heat to the processed materials.

Precision welding by laser beam is an excellent choice not only because of its penetration-free results – it also enables accurate, pinpoint work in areas that are hard to reach.

Laser welding is also tangibly and visibly convincing due to:

-

contactless and force-free welding

-

low heat penetration and therefore minimal material distortion

-

exactly reproducible geometry of the weld area

-

laser welding even in depressions and hollows as well as through windows

-

highly accurate repeatability – through precisely defined welding parameters and lack of tool wear

-

no discolorations

-

smooth surface

-

high-quality, visually appealing welding seam